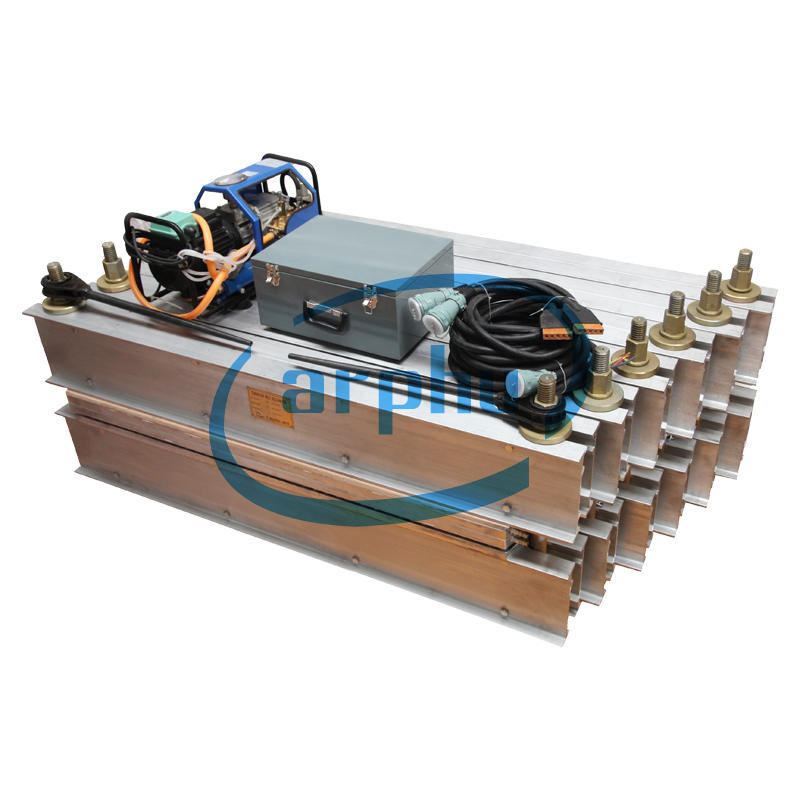

Conveyor Belt Vulcanizer

Arphu specializes in the designing and manufacturing quality conveyor belt vulcanizers, conveyor belt maintenance materials, hot splicing tools and equipment to power plant, steel plant, cement plant, mine, port, chemical industry etc. Besides supplies the conveyor belt vulcanizing press, Arphu can also supply a series of auxiliary tools to the conveyor system.When the on-site splicing is correctly done with the portable belt vulcanizing machine, the belt joints shall be smooth, belt strength shall be reach over 90% of the original belt, through hot splicing it shall reduce the abrasion of roller and extend the conveyor and belt's working life.

Conveyor belt vulcanizer is ideally for splicing & repairing EP conveyor belt, rubber conveyor belt ,Nylon conveyor belt and Steel cord conveyor belt etc.

Features of our Conveyor Belt Vulcanizer:

1. Heating Plate: lightweight, portable, pressure and temperature uniformity;

2. Water Plate: high pressure can reach Max. 2.0 MPa (20 bars or 290 psi);

3. Cross Beam: lightweight & high tensile aluminum alloy;

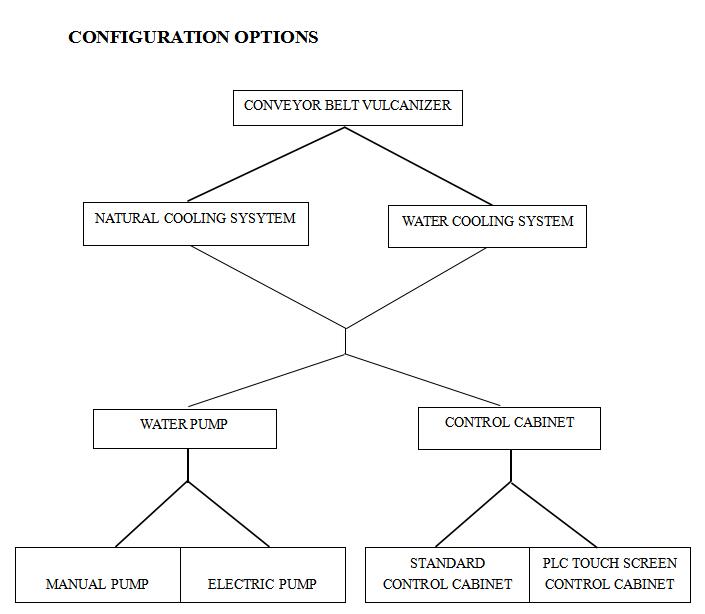

The configuration options are described in the following sections.

1) Heating plates of the vulcanizers are available for rhombic, rectangular and modular type (two or more sets of heating plates together).

Modular conveyor belt vulcanizer can be applied to Belt width 3200 mm maximum.

Special design and production service is offered as per requirements of clients.

1) Natural cooling system or water cooling system:

Feature of water cooling system: Rapid integral cooling fitted on both plates, belt vulcanizer could be dismantled within 5-10 minutes.

2) Manual pump or electrical pump

3) Standard control cabinet or PLC control cabinet

The conveyor belt vulcanizing press is widely used in the field of metallurgy, mining, power plants, ports, building materials, cement, coal mine, chemical industry, etc.

The machine can be customized to suit your actual splicing needs.

MAIN TECHNICAL PARAMETERS:

1. Vulcanization pressure: 1.0-2.0 MPa;

2. Vulcanization temperature: 145°C;

3. Difference in surface temperature of vulcanized plate: ± 3°C;

4. Heating up time ( at normal temperature to 145°C )<30 minutes;

5. Voltage: 220V/ 380V/415V/440V/480V/550V/660V, 50/60HZ, 3PHASES;

6. Temperature Controller adjustment range: 0 to 199°C;

7. Timer adjustment range: 0 to 99 minutes.

TECHNICAL PARAMETER TABLE OF CONVEYOR BELT VULCANIZER

|

Belt Width |

Model |

Heating Plate Size |

Power |

Dimension |

PKG DIMENSION |

Weight |

|

(MM) |

DLCBV |

L*W*T (MM) |

KW |

L*W*H (MM) |

L*W*H (MM) |

KGS |

|

650 |

DLCBV-650×830 |

883×820×31 |

10.8 KW |

1140×883×585 |

1450*950*860 |

440 |

|

DLCBV-650×1000 |

1064×820×31 |

13 KW |

1140×1064×585 |

1450*1120*860 |

530 |

|

|

800 |

DLCBV-800×830 |

883×995×31 |

12.7 KW |

1320×883×585 |

1600*950*860 |

515 |

|

DLCBV-800×1000 |

1064×995×31 |

15.4 KW |

1320×1064×585 |

1600*1120*860 |

630 |

|

|

1000 |

DLCBV-1000×830 |

883×1228×31 |

15 KW |

1450×883×585 |

1830*950*860 |

600 |

|

DLCBV-1000×1000 |

1064×1228×31 |

18 KW |

1450×1064×585 |

1830*1520*1000 |

715 |

|

|

1200 |

DLCBV-1200×830 |

883×1431×31 |

18.2 KW |

1700×883×750 |

2100*950*1120 |

800 |

|

DLCBV-1200×1000 |

1064×1431×31 |

22 KW |

1700×1064×750 |

2100*1120*1120 |

912 |

|

|

1400 |

DLCBV-1400×830 |

883×1653×31 |

20.6 KW |

1950×883×750 |

2280*950*1170 |

885 |

|

DLCBV-1400×1000 |

1064×1653×31 |

24.6 KW |

1950×1064×750 |

2280*1120*1170 |

1050 |

|

|

1600 |

DLCBV-1600×830 |

883×1867×31 |

22.8 KW |

2150×883×795 |

2510*950*1170 |

1130 |

|

DLCBV-1600×1000 |

1064×1867×31 |

27.2 KW |

2150×1064×795 |

2550*1120*1270 |

1325 |

|

|

1800 |

DLCBV-1800×830 |

883×2079×31 |

25 KW |

2380×883×900 |

2700*950*1320 |

1420 |

|

DLCBV-1800×1000 |

1064×2079×31 |

30 KW |

2380×1064×900 |

2750*1120*1310 |

1630 |

|

|

2000 |

DLCBV-2000×830 |

883×2303×31 |

27.4 KW |

2620×883×980 |

2960*950*1310 |

1560 |

|

DLCBV-2000×1000 |

1064×2303×31 |

33 KW |

2620×1064×980 |

2960*1170*1310 |

1824 |

|

|

2200 |

DLCBV-2200×830 |

883×2478×31 |

29.8 KW |

2883×883×980 |

3160*950*1310 |

1720 |

|

DLCBV-2200×1000 |

1064×2478×31 |

35.8 KW |

2883×1064×980 |

3160*1170*1310 |

2030 |