How to maintenance and repair conveyor belt

How to maintenance and repair conveyor belt

Industrial conveyor belt in every industry, from distribution centers to facilities and plants, undergo rigorous working conditions. Maintenance and engineering managers know even the best-designed conveyor belts require repairs and maintenance, which is why knowing how to efficiently repair belts and prevent future damage is very important.

How to maintenance and repair conveyor belt?

Frankly speaking, there are three ways to maintenance and repair conveyor belt:

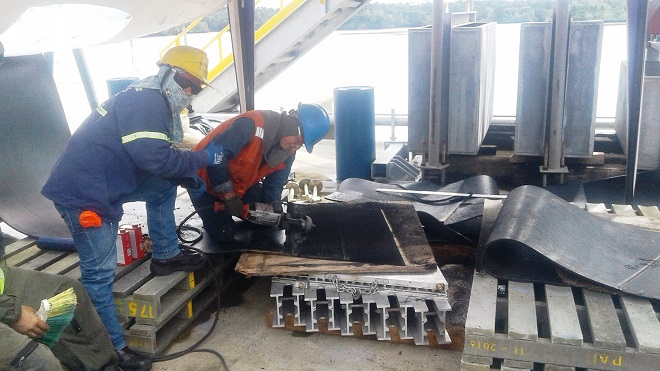

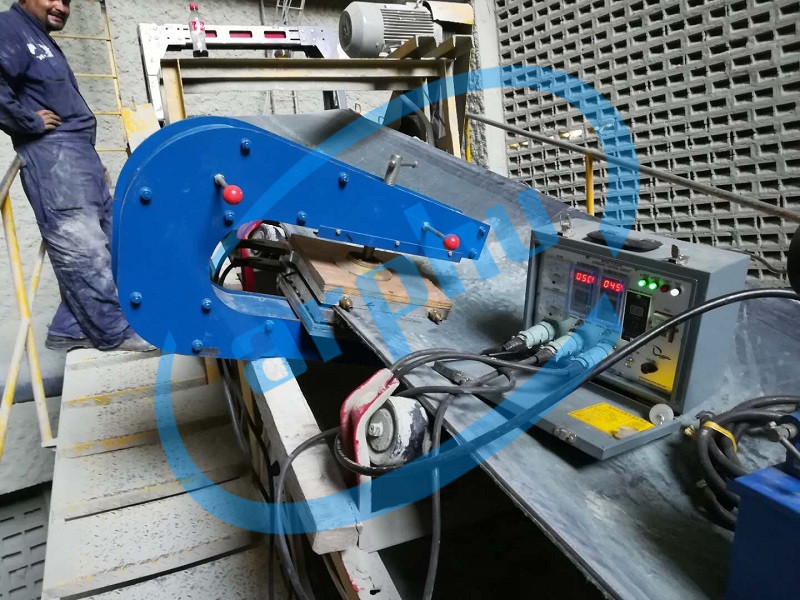

1. The first way: hot splicing by conveyor belt vulcanizers, it's also called Vulcanizing presses;

2. The second way: cold connection by glue;

3. The last way: repair by mechanical chain.

For this FAQ, we mainly discuss about the hot splicing belt by conveyor belt vulcanizer. The ideal effective for

repairing or splicing conveyor belt will obey the principle of same tension strength and same service life

comparing with new original conveyor belt, and only adopts hot splicing advanced technology.

The main purpose for cold splice and mechanical method is to save operation time and lessen the loss. So it’s not

the best way to choose cold splice and mechanical splice to replace hot conveyor belt vulcanizer.

The advantages for hot splice of conveyor belt by conveyor belt vulcanizers are almost same service life and same

tension strength comparing with new and original conveyor belt. Conveyor Belt Vulcanizer or Conveyor Belt

Vulcanizing Press is the best way to repair and splice belt.